Our Products

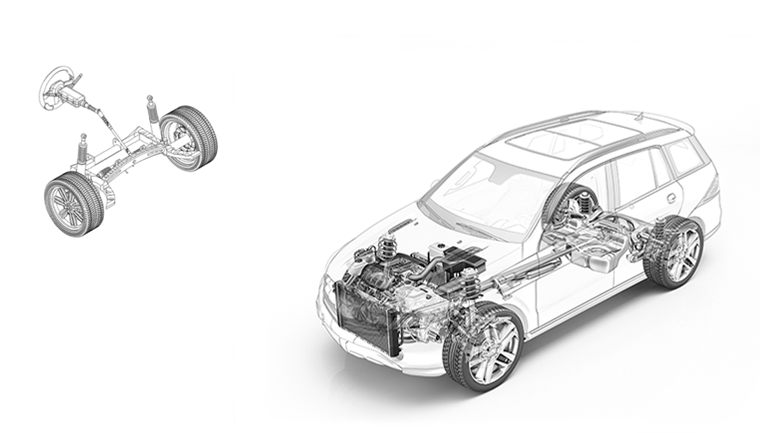

Typical End Applications

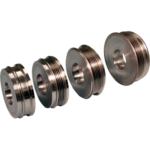

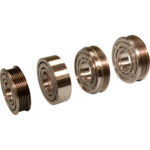

- Air Conditioning Compressor

- Electro-magnetic clutch and brake

- Clutched Supercharger

- Clutched Liquid Heat Generator

- Clutched Water Pump

- Electro-magnetic locking differential

- 4WD Transfer Case

- Power Transfer Unit

- Electro-magnetic Control Device

- Hybrid / electric drive systems

- Powertrain components

- Clutched Roots type blower

About Us

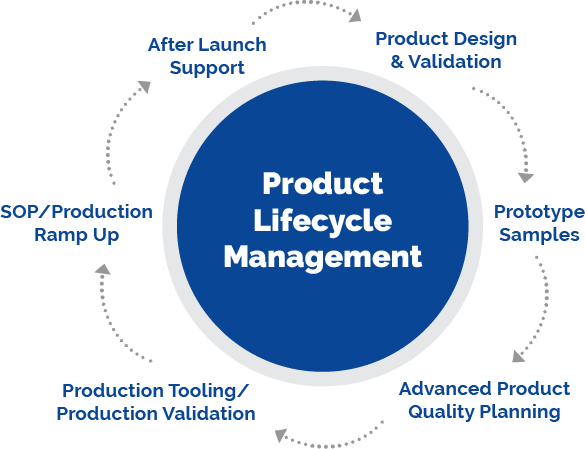

Product Lifecycle Management

- Product Design and Validation

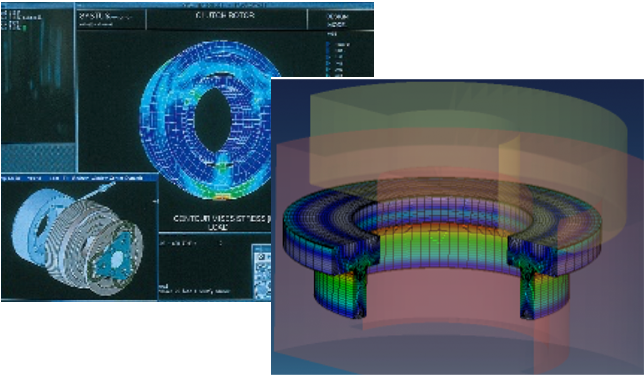

- 2D / 3D model and FEM Analysis (Structural, EM, Thermal, Plasticity)

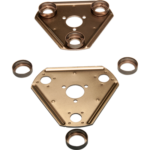

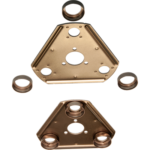

- Prototype Samples

- Used for design validation (DV) test

- Dimensionally a copy of final design

- Advanced Product Quality Planning

- Regularly scheduled Advance Product Quality Planning (APQP) meetings to evaluate progress against milestones

- Production Tooling / Production Validation

- Install production tooling and complete Production Validation (PV) test

- SOP / Production Ramp Up

- Align production to customer ramp up requirements

- After Launch Support

- Value Analysis / Value Engineering (VAVE) and Material Cost Reduction (MCR) ongoing activity

Engineering

Ogura utilizes computer aided design, 3D modeling and computer analysis prior to cutting the first piece of metal for prototype components. Computer analysis includes finite element analysis and computer analysis of the magnetic flux circuit. Our in-house prototype shop fabricates economical prototypes using production-intent processes for short lead times.